In this article we want to explain the ins and outs of hydraulic power pack. A vital piece of equipment that is used with so many machines we see every day. In a nutshell, hydraulic powerpacks are self contained units that are used instead of a built in power supply for hydraulic machinery. Hydraulic power uses fluid to transmit power from one location to another in order to run a machine. It really is as simple as that.

We will explore the fascinating world of hydraulic systems, focusing specifically on Hydraulic Power Pack Machines. These systems are a critical component in various industrial processes, offering efficiency, precision, and reliability. If you’re looking to understand how hydraulic power packs function and how they benefit your operations, this post is for you.

What is a Hydraulic Power Pack?

Generally we provide four different types of hydraulic power pack. You can pick from a standard powerpack, a mini powerpack, a micro powerpack or a bespoke powerpack.

The standard hydraulic powerpack uses a standard range of modular components and is ideal for the most demanding industrial applications. The mini powerpack is ideal for applications requiring up to 5.5kW. The micro hydraulic power packs were originally produced for mobility applications, so are great for when space is limited. Finally, if none of these seem to fit your needs then we offer bespoke hydraulic powerpacks ensuring your application gets the hydraulic powerpack it requires.

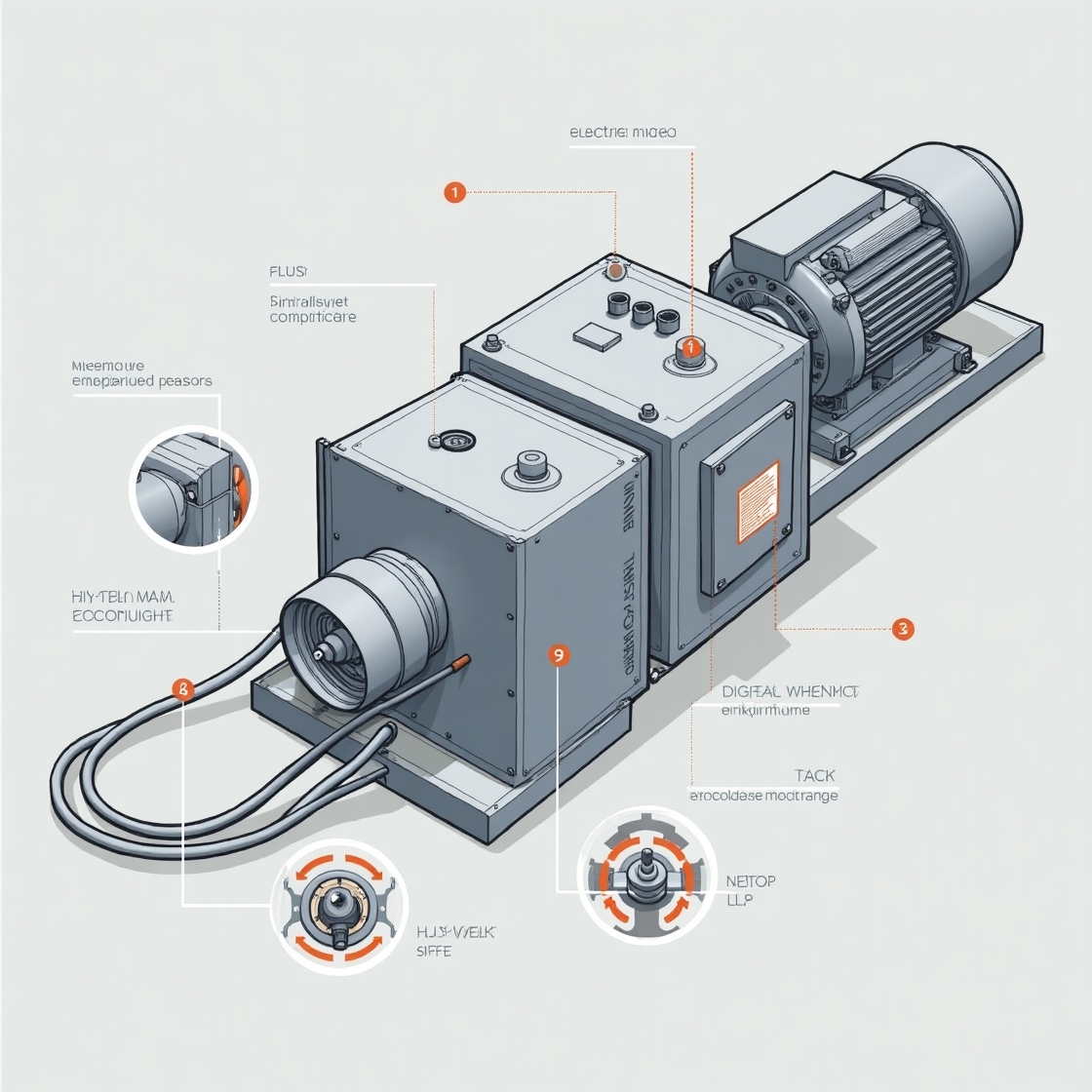

Key Components of a Hydraulic Power Pack

A typical hydraulic power pack consists of several critical components that work together to generate hydraulic power:

- Hydraulic Pump: This is the core component that generates the flow of hydraulic fluid. It converts mechanical energy into hydraulic energy.

- Electric Motor: The motor powers the hydraulic pump, ensuring a constant flow of hydraulic fluid under pressure.

- Hydraulic Fluid Reservoir: This is where the hydraulic fluid is stored. The fluid serves as the medium for power transmission and lubrication.

- Control Valve: These valves control the direction, flow, and pressure of the hydraulic fluid, ensuring that the right amount of force is delivered to the equipment being operated.

- Pressure Relief Valve: This safety feature helps protect the hydraulic system by preventing excessive pressure buildup.

- Hydraulic Fluid: The hydraulic fluid is responsible for transmitting force within the system, as well as cooling and lubricating the system’s components.

- Filter: Filters are used to keep the hydraulic fluid clean, preventing contamination that could cause damage to sensitive parts of the system.

How Does a Hydraulic Power Pack Work?

The operation of a hydraulic power pack is relatively simple, but efficient. Here’s a step-by-step breakdown of how it works:

- Power Generation: The electric motor drives the hydraulic pump. The pump draws hydraulic fluid from the reservoir and pressurizes it.

- Fluid Flow and Control: The high-pressure fluid is directed through control valves that regulate the flow and direction of the fluid to the desired location.

- Power Transmission: The pressurized hydraulic fluid is sent to the machinery or actuator where it performs the required work, such as lifting, pressing, or rotating.

- Return to Reservoir: Once the fluid has done its work, it returns to the reservoir to be recirculated. The system ensures continuous fluid flow, enabling the hydraulic machinery to operate seamlessly.

- Safety Mechanisms: Throughout the process, the pressure relief valve and filter ensure the system runs safely and efficiently, protecting components from potential damage caused by excessive pressure or contamination.

Benefits of Hydraulic Power Packs

Hydraulic power packs offer numerous advantages that make them essential in various industries:

- High Power Density: Hydraulic systems are compact yet capable of delivering substantial force, making them ideal for heavy-duty applications.

- Precision Control: Hydraulic power packs allow for precise control over speed, force, and direction, offering versatility in operation.

- Reliability and Durability: With proper maintenance, hydraulic systems are known for their longevity and robustness in demanding environments.

- Energy Efficiency: Hydraulic power packs are energy-efficient compared to some mechanical systems, reducing operational costs.

Applications of Hydraulic Power Pack Machines

Hydraulic power packs are used in a wide range of applications across many industries. Some of the most common applications include:

- Construction Machinery: Hydraulic power packs are used in excavators, cranes, and bulldozers for lifting and moving heavy materials.

- Manufacturing Equipment: Machines such as injection molding machines, presses, and conveyors rely on hydraulic power packs for precise movements.

- Automotive Industry: In car manufacturing, hydraulic systems assist in tasks such as assembly, lifting, and testing.

- Aerospace: Aircraft landing gear, cargo handling systems, and other vital functions often rely on hydraulic power systems.

Conclusion

A Hydraulic Power Pack Machine is a powerful and efficient way to generate hydraulic energy, enabling machinery to perform a wide range of tasks with precision and reliability. At Radhey Krishan Industries, we specialize in providing high-quality hydraulic power packs designed to meet the demanding needs of various industrial applications. Whether you need a hydraulic system for construction, manufacturing, or any other sector, we are committed to delivering solutions that help your business run smoothly and efficiently.

So, interested in our Power Packs? Come on over to the main website and see what we can do for your Hydraulic Power Pack Needs