Press machines play an important role in several industrial applications, from metalworking to plastic molding. They are used to shape, cut, or assemble materials through the application of force. Different types of press machines cater to specific manufacturing needs. In this blog, we will explore the various types of press machines and their uses. Read More : Automatic Hydraulic Press Machine About Press Machines A press machine, also known as a forming press, This is a machine that uses pressure to change the shape of a material. Press machines are used in the manufacturing industry to shape, cut, or form materials like metal, wood, and plastic. Hydraulic Press Machines Hydraulic press machines are widely used in industrial applications for shaping, molding, and compressing materials with precision and efficiency. These machines operate using a hydraulic cylinder that generates force through the application of hydraulic fluid pressure. These mechanical presses, hydraulic press machines provide uniform force throughout the operation, ensuring high accuracy and better control.One of the key advantages of H Frame Hydraulic Press Manufacturers is their ability to handle heavy-duty tasks with ease. They are commonly used in metal forming, deep drawing, forging, and composite material processing. Additionally, they are preferred for applications requiring high tonnage, as they can generate immense force while maintaining operational stability.Hydraulic presses come in different configurations, like C-frame, H-frame, and four-post designs, catering to various industrial needs. They are widely used in the automotive, aerospace, construction, and manufacturing industries for producing high-strength components.Another benefit of hydraulic press machines is their safety and energy efficiency. Since they do not rely on a flywheel mechanism like mechanical presses, they offer smoother operation and reduced noise levels. With advancements in automation, modern hydraulic presses are equipped with programmable controls for improved productivity and precision. Mechanical Press Machines Mechanical press machines are mainly used in industrial applications for cutting, shaping, and forming metal sheets. These machines operate using a motor-driven flywheel, which stores and transfers energy through a crankshaft mechanism. Known for their high-speed operation, mechanical presses are ideal for mass production industries such as automotive, electronics, and metal fabrication.Their key advantages include precision, efficiency, and durability. They are commonly used for stamping, punching, and blanking operations. Mechanical presses come in various configurations, including single-crank, double-crank, and eccentric presses, catering to different industrial needs. Pneumatic Press Machines Pneumatic press machines use compressed air to generate force, making them ideal for light-duty applications that require speed and precision. These presses are commonly used in industries like electronics, packaging, and assembly for operations such as riveting, embossing, and small-scale forming.Hydraulic or mechanical presses, pneumatic press machines offer quick response times, low maintenance, and energy efficiency. They are also known for their smooth operation and ease of automation, making them a preferred choice for high-speed production environments. Servo Press Machines Servo press machines utilize advanced servo motor technology to deliver precise force and motion control. Unlike traditional hydraulic or mechanical presses, these machines provide exceptional accuracy, programmability, and energy efficiency. They are widely used in industries such as aerospace, automotive, and electronics, where high precision is required.Servo presses offer benefits like reduced noise, minimal maintenance, and better force distribution. Their ability to adjust speed and pressure dynamically makes them ideal for delicate and complex forming operations. Hydro Mechanical Press Machines Hydro mechanical press machines combine the benefits of hydraulic and mechanical press systems, offering both high-speed operation and controlled force application. These machines use a hydraulic system to generate initial force and a mechanical system to complete the pressing action, ensuring efficiency and precision.They are widely used in metal forming, deep drawing, and composite material processing industries. With their ability to handle high loads while maintaining accuracy, they are ideal for heavy-duty manufacturing applications. C-Frame Press Machines C-Frame press machines, also known as gap-frame presses, feature a C-shaped structure that provides easy access to the work area from three sides. These presses are compact, space-efficient, and ideal for light to medium-duty applications such as bending, punching, stamping, and pressing.Due to their open design, C-Frame presses allow for quick loading and unloading of materials, improving productivity. They are commonly used in industries like automotive, metal fabrication, and electronics. Forging Press Machines Forging press machines are specifically designed for shape metal components by applying high-pressure force, making them essential for industries like automotive, aerospace, and heavy machinery manufacturing. These presses use hydraulic or mechanical systems to compress metal, enhancing its strength and durability.Forging presses are ideal for producing high-precision, high-strength parts such as gears, shafts, and structural components. They offer consistent force application, making them suitable for mass production. One Of The Best Press Machines In India When it comes to high-quality and reliable press machines in India, Radhey Krishan Industries stands out as a leading manufacturer. Our press machines are well known for their precision, durability, and advanced technology, making them suitable for a wide range of industrial applications.Whether you need hydraulic, mechanical, pneumatic, servo, or forging press machines, we offer solutions tailored to meet the needs of the automotive, metal fabrication, and heavy machinery industries. With robust construction and efficient performance, our machines ensure superior productivity and long-lasting reliability.Choose Radhey Krishan Industries for the best press machines in India, it’s designed with excellence for manufacturing. We offer best quality press machines to your industrial needs at affordable prices. Contact us to learn more about our services to find the perfect press machine for your operations or industrial needs.

A Industrial Hydraulic press is a machine that uses hydraulic force to shape, mold, or compress materials. It operates on Pascal’s principle, where pressure applied to a confined fluid is transmitted equally in all directions. Working involves a hydraulic cylinder, piston, and fluid to generate immense pressure. Safety is crucial, requiring proper training, maintenance, and protective gear. Advantages include high efficiency, precision, and durability, while disadvantages involve high initial costs and potential oil leaks. Applications span industries like automotive, aerospace, and manufacturing. Radhey Krishan Industries provides high-quality hydraulic presses for diverse industrial needs. Also Read Us: Top 5 Hydraulic Press Machine Manufacturer in India What is a Hydraulic Press Machine? A hydraulic press is a kind of mechanical machine that uses liquid to transfer energy to shape and deform various types of metals. It works on Pascal’s principle. The machine is mainly used for uplifting the Application of smaller forces. Pascal’s principle states that the intensity of pressure in a static fluid is transmitted equally in all directions. The hydraulic presses, commonly provided by hydraulic press manufacturers, contains three parts: the mainframe, the power system, and the hydraulic control system. In this, the pressure in a liquid is applied by a pump that works like a pump and creates mechanical force. Various types of presses, such as the industrial hydraulic press, H-frame hydraulic press, and C-frame hydraulic press, are designed to handle different industrial tasks. Hydraulic Press Machine Working : Generally, multiple small rams are used rather than one large ram because it is easy to control the thrust forces as compared to large sizes. The number of rams depends upon the working load. The hydraulic pressure of fluid drives the ram. A pump and hydraulic accumulator are used to supply the high-pressure liquid. The Hydraulic accumulator works as a junction point between the pump and the rams. When the press is stationary, a hydraulic accumulator stores the high-pressure liquid. When strong thrust is necessary for operation, a hydraulic press is used. This working mechanism is typical for machines like the 20 ton hydraulic press, 50 ton hydraulic press, and even larger presses. Working of a Hydraulic Press A hydraulic press functions through a series of steps: Safety Measures for Hydraulic Press Machines Hydraulic presses operate under high pressure and can pose serious risks if not handled properly. Below are some essential safety measures: Advantages of Hydraulic Press Machine : As compared to the manual machine the hydraulic press machine has a lighter weight with a small number of parts used for forming the shapes of sheet metal. The main advantages of Hydraulic press machines are the following: Disadvantages: Applications: Why Choose a Hydraulic Press? When selecting a pressing solution, a hydraulic press stands out due to its numerous advantages. Here’s why you should choose a hydraulic press: Conclusion: Hydraulic presses are an essential part of various industries due to their high efficiency, versatility, and precision. While they offer significant advantages, proper safety measures must be taken to prevent accidents and ensure smooth operation. Understanding their working principles, benefits, and applications can help businesses choose the right hydraulic press for their specific needs. For high-quality hydraulic presses, Radhey Krishan Industries provides top-of-the-line machinery with advanced features and excellent performance. Contact us today for the best hydraulic press solutions tailored to your industrial requirements!

Struggling to find reliable hydraulic press manufacturers? With numerous options available, how can you ensure top quality and value for your investment? Let’s explore the top players in the industry to help you make an informed decision.The hydraulic press machine is an essential tool in the manufacturing sector, used for various applications like metal forming, plastic molding, and assembly. As industries continue to evolve and demand more efficient machinery, the importance of high-quality hydraulic press machines is growing. India, with its booming manufacturing industry, is home to several reputable hydraulic press machine manufacturers.In this blog, we’ll look at the top hydraulic press machine manufacturers in India, including Radhey Krishan Industries, one of the leading names in the sector. Also Read Us: What is Hydraulic Press? 1. Radhey Krishan Industries Radhey Krishan Industries is one of India’s most trusted names in the hydraulic press machine manufacturing industry. Known for their high-quality machinery, they specialize in producing Industrial Hydraulic Press Machines that are widely used across various industries such as automotive, heavy machinery, and aerospace. Radhey Krishan Industries is renowned for delivering custom hydraulic press machines tailored to meet the specific requirements of clients. With a strong commitment to innovation, precision, and durability, they offer hydraulic presses that deliver superior performance, ensuring smooth and efficient operations. Our team uses Premium Quality Raw for Manufacturing Hydraulic Press Machines. That is a strong reason we are working as India’s Top Best Manufacturer and Supplier of Hydraulic Press Machines for the last 20+ Years. Key Features of Industrial Hydraulic Press Machine: High Force Output – Generates powerful force for heavy-duty tasks like molding, forging, and metal forming. Precision and Accuracy – Provides consistent, accurate results with fine control over force and pressure. Customization Options – Machines can be tailored to specific needs, including size, capacity, and features. Durability – Built with robust materials for long-lasting performance in tough industrial environments. Energy Efficiency – Consumes less energy compared to mechanical presses, offering cost-effective operations. Safety Features – Includes guards, emergency stops, and overload protection for operator safety. Key Features of Radhey Krishan Industries: 2. M/r Santech Group M/r Santech Group is one of India’s leading manufacturers of hydraulic press machines. They have earned a solid reputation for providing high-performance machines to industries such as automotive, metalworking, and manufacturing. Their hydraulic presses are designed to offer high force output, precision, and reliability. Santech Group also offers a range of other industrial machinery, making them a versatile player in the market. 3. Reet Machinery Co. Reet Machinery Co. is another prominent manufacturer of hydraulic presses in India. The company has been serving the industrial sector for decades, offering high-quality hydraulic press machines used in heavy-duty applications. Reet Machinery Co. is known for its technologically advanced designs that ensure high productivity and reliability in industries like metalworking, packaging, and more. 4. Ruhani Engineering Ruhani Engineering is a well-established name in the hydraulic press industry, offering state-of-the-art hydraulic presses for various sectors such as automotive, manufacturing, and metal forming. Their Industrial hydraulic presses are highly durable and efficient, capable of handling heavy-duty operations with ease. The company’s dedication to quality and performance ensures their machines consistently exceed customer expectations. 5. HARSHALI Group The HARSHALI Group is a prominent name in the manufacturing of hydraulic presses in India. They specialize in designing and producing a variety of hydraulic press machines, including deep drawing presses, forging presses, and H-frame presses. Known for their commitment to quality and customer satisfaction, HARSHALI Group has built a strong brand presence in the Indian market. Conclusion The hydraulic press machine is an indispensable part of modern manufacturing, and India boasts a number of manufacturers providing high-quality, innovative solutions to industries worldwide. Among these, We stands out as one of the most trusted suppliers, specializing in Industrial hydraulic presses. Their commitment to quality, customization, and after-sales service makes them a preferred choice for businesses in need of reliable and durable hydraulic presses. If you are looking for top-notch hydraulic press machines in India, be sure to consider Radhey Krishan Industries for all your industrial machinery needs. Their expertise in H Frame Hydraulic Press Machines and dedication to delivering the best products make them one of the top manufacturers in the country.

Power press machines play a crucial role in the manufacturing industry, providing the force and precision required for metal forming, cutting, punching, and pressing operations. As an essential piece of industrial equipment, power press machines help manufacturers improve efficiency and maintain high production standards. In this comprehensive guide, we will explore the different types of H Frame Hydraulic Press Manufacturers, their applications, benefits, and factors to consider when choosing the right machine for your business. What is a Power Press Machine? A Power Press Machine is a mechanical device used to shape, cut, bend, and form metal sheets with high precision and efficiency. It plays a crucial role in various sheet metal fabrication processes, making it indispensable in modern manufacturing. This highly versatile tool performs both forming and cutting of metals simultaneously, ensuring faster production cycles and improved accuracy. It’s one of the most adaptable sheet metal machines on the market, and it’s employed in a variety of heavy industrial applications. Previously, manually shaping the metal sheet required a considerable deal of labor and force. But with the help of a Power press , it will be easier to cut, bend, press, and form the metal sheet into different shapes and sizes by applying a high amount of pressure. Benefits of Using Power Press Machines 1. Increased Efficiency Power press machines significantly reduce production time and labor costs by automating metalworking processes. 2. High Precision and Accuracy With advanced control systems, these machines ensure precise and consistent output, reducing material wastage. 3. Versatility Power press machines can handle a wide range of operations, including cutting, bending, punching, and stamping, making them suitable for diverse industries. 4. Cost-Effective Manufacturing By improving production speed and reducing material wastage, power press machines lower the overall manufacturing cost. 5. Enhanced Safety Modern power press machines come with safety features such as emergency stop buttons, sensors, and protective guards to prevent workplace accidents. Types of Power Press Machines: C-Type Power Press Machines: Known for their C-shaped frame, these machines provide excellent accessibility and are commonly used for operations like punching, stamping, and bending. H-Type Power Press Machines: Designed with an H-shaped frame, these machines offer higher stability and strength, suitable for heavy-duty applications. Hydraulic Power Press Machines: Utilizing hydraulic cylinders to generate force, these machines provide precise control over the pressing process and are ideal for complex shaping tasks. Applications of Power Press Machines: Power Press Machines are widely used across various industries due to their efficiency and versatility. Key applications include: What are the Uses of Power Press? What are the benefits of Power Press Machines? Safety Measures While Using a Power Press Machine : Using a Power Press Machine safely is crucial since it falls under the heavy machine category. Follow these safety measures: Why Choose Radhey Krishan Industries for Power Press Machines? At Radhey Krishan Industries, we specialize in manufacturing high-quality power press machines designed for precision, durability, and efficiency. Our machines are engineered using the latest technology to meet the diverse needs of industries such as automotive, aerospace, construction, and more. Our Key Features: By choosing Radhey Krishan Industries, you invest in reliable, high-performance power press machines that drive efficiency and profitability for your business. Conclusion Power press machines are indispensable in modern manufacturing, offering high-speed, precise, and cost-effective metalworking solutions. Whether you need a mechanical, hydraulic, pneumatic, or servo press, choosing the right machine will significantly impact your productivity and profitability. For top-quality power press machines, trust Radhey Krishan Industries. Contact us today to learn more about our innovative solutions and how we can help optimize your production process! Website: https://www.radheykrishanindustries.com/ Mobile: +91-7836842828 Email: rkigyan@gmail.com

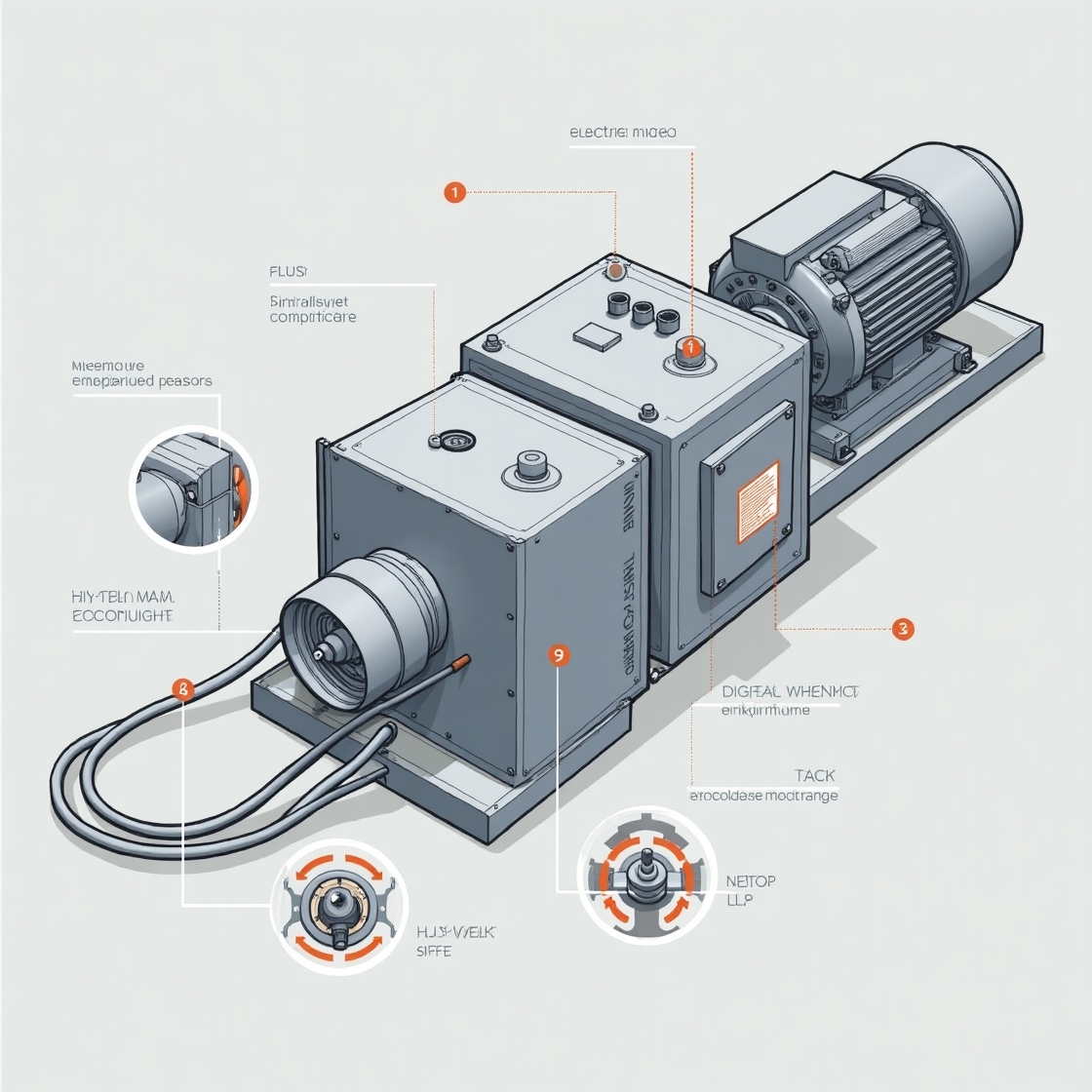

A hydraulic power pack is a self-contained unit designed to supply hydraulic power to various industrial and mobile applications. It consists of several components, including a hydraulic pump, reservoir, motor, valves, and control units, which work together to generate, control, and distribute hydraulic energy to drive machinery and equipment. How Does a Hydraulic Power Pack Work? Hydraulic power packs operate by converting mechanical energy into hydraulic energy. The electric motor or internal combustion engine drives the hydraulic pump, which pressurizes the hydraulic fluid stored in the reservoir. This pressurized fluid is then directed through control valves to hydraulic cylinders or motors, allowing the system to perform various tasks such as lifting, pushing, or rotating. Key Components of a Hydraulic Power Pack: Types of Hydraulic Power Packs: Applications of Hydraulic Power Packs: Advantages of Hydraulic Power Packs: Maintenance Tips for Hydraulic Power Packs: Conclusion Hydraulic power packs play a vital role in powering hydraulic systems across multiple industries. With their efficient and reliable performance, they offer a cost-effective solution for powering heavy-duty equipment and machinery. Whether for industrial or mobile applications, selecting the right hydraulic power pack can significantly enhance operational productivity and efficiency.

Radhey Krishan Industries, dedicated to providing you with high-quality industrial machinery and equipment that meet the latest technological standards. A hydraulic press is a machine that uses hydraulic pressure to shape materials like rubber, plastic, metals, and wood. It’s also known as a Bramah press after its inventor, Joseph Bramah.

In this article we want to explain the ins and outs of hydraulic power pack. A vital piece of equipment that is used with so many machines we see every day.

In a nutshell, hydraulic powerpacks are self contained units that are used instead of a built in power supply for hydraulic machinery. Hydraulic power uses fluid to transmit power from one location to another in order to run a machine. It really is as simple as that.

We will explore the fascinating world of hydraulic systems, focusing specifically on Hydraulic Power Pack Machines. These systems are a critical component in various industrial processes, offering efficiency, precision, and reliability. If you’re looking to understand how hydraulic power packs function and how they benefit your operations, this post is for you.

Understanding your specific requirements is key when selecting the perfect H Frame Hydraulic Press Machine. Radhey Krishan Industries, a trusted name in the industry, offers a wide range of high-quality hydraulic press machines to meet diverse industrial needs. Here’s a comprehensive guide to help you choose the right one for your applications. 1. Identify Your Application Requirements The first step in selecting the right hydraulic press machine is understanding your application. Whether you need it for punching, bending, pressing, or molding, the type of task will influence the machine’s tonnage, bed size, and design. Tonnage Capacity: Determine the force required for your operations. Radhey Krishan Industries offers machines ranging from low-tonnage to heavy-duty models. Bed Size: Ensure the press bed is large enough to accommodate your materials and molds. Stroke Length: Choose a machine with an appropriate stroke length for your process. 2. Consider Build Quality and Design The durability and efficiency of an H Frame Hydraulic Press Machine depend on its construction and design. Look for features like: Robust Frame: A sturdy H-frame ensures stability and longevity. High-Quality Components: Machines from Radhey Krishan Industries are equipped with premium hydraulic systems and precision-engineered parts. Ease of Operation: Opt for models with user-friendly controls for better productivity. 3. Evaluate Safety Features Safety should be a top priority when working with hydraulic presses. Check for: Emergency Stop Mechanisms: To halt operations instantly in case of an emergency. Overload Protection: Prevents damage to the machine and ensures operator safety. Proper Guarding: Shields to protect operators from accidental contact with moving parts. 4. Check for Customization Options Radhey Krishan Industries specializes in offering customized solutions tailored to your unique requirements. Discuss your needs with their team to design a machine that perfectly fits your operations. 5. Assess Power and Efficiency Energy-efficient machines can reduce operational costs in the long run. Ensure the hydraulic press has: Efficient Power Consumption: Machines with optimized hydraulic systems minimize energy usage. Precision Controls: Advanced features for accurate and consistent performance. 6. Look for After-Sales Support Reliable customer support and maintenance services are essential for long-term operation. Radhey Krishan Industries provides: Comprehensive Warranties: Assurance for parts and labor. Expert Assistance: Dedicated technicians for installation, troubleshooting, and maintenance. Availability of Spare Parts: Ensures minimal downtime in case of repairs. 7. Compare Prices and ROI While cost is an important factor, focus on the overall value the machine brings. A high-quality hydraulic press from Radhey Krishan Industries is an investment that offers durability, efficiency, and long-term reliability. Conclusion Choosing the right H Frame Hydraulic Press Machine requires careful evaluation of your operational needs, machine specifications, and support services. With Radhey Krishan Industries, you gain access to cutting-edge hydraulic press machines designed for precision and performance. Contact their team today to find the perfect solution for your industrial applications.

A Hydraulic Press is a machine that uses hydraulic pressure to compress, mold, or shape various materials. It operates on the principle of Pascal’s law, which states that when pressure is applied to a confined fluid, it is transmitted equally in all directions. This makes hydraulic presses ideal for tasks that require significant force, such as metal forming, plastic molding, and even waste material compaction.

Hydraulic machines are remarkable devices that leverage the principles of hydraulics to perform work efficiently and effectively. From construction equipment to automotive systems, these machines are integral to various industries. In this blog, we’ll explore the fundamental concepts behind hydraulic machines, how they operate, and their numerous applications.